- Located in Shelbyville Township, MI at our Parent Company’s facilities

- ISO/IEC 17025:2017

- Accredited June 29, 2021

- Recertified May 3, 2022 with no nonconformances

- Mechanical Testing

- Acceleration

- Angle

- Displacement

- Durometer

- Force

- Frequency

- Torque

- Torsional Spring Rate

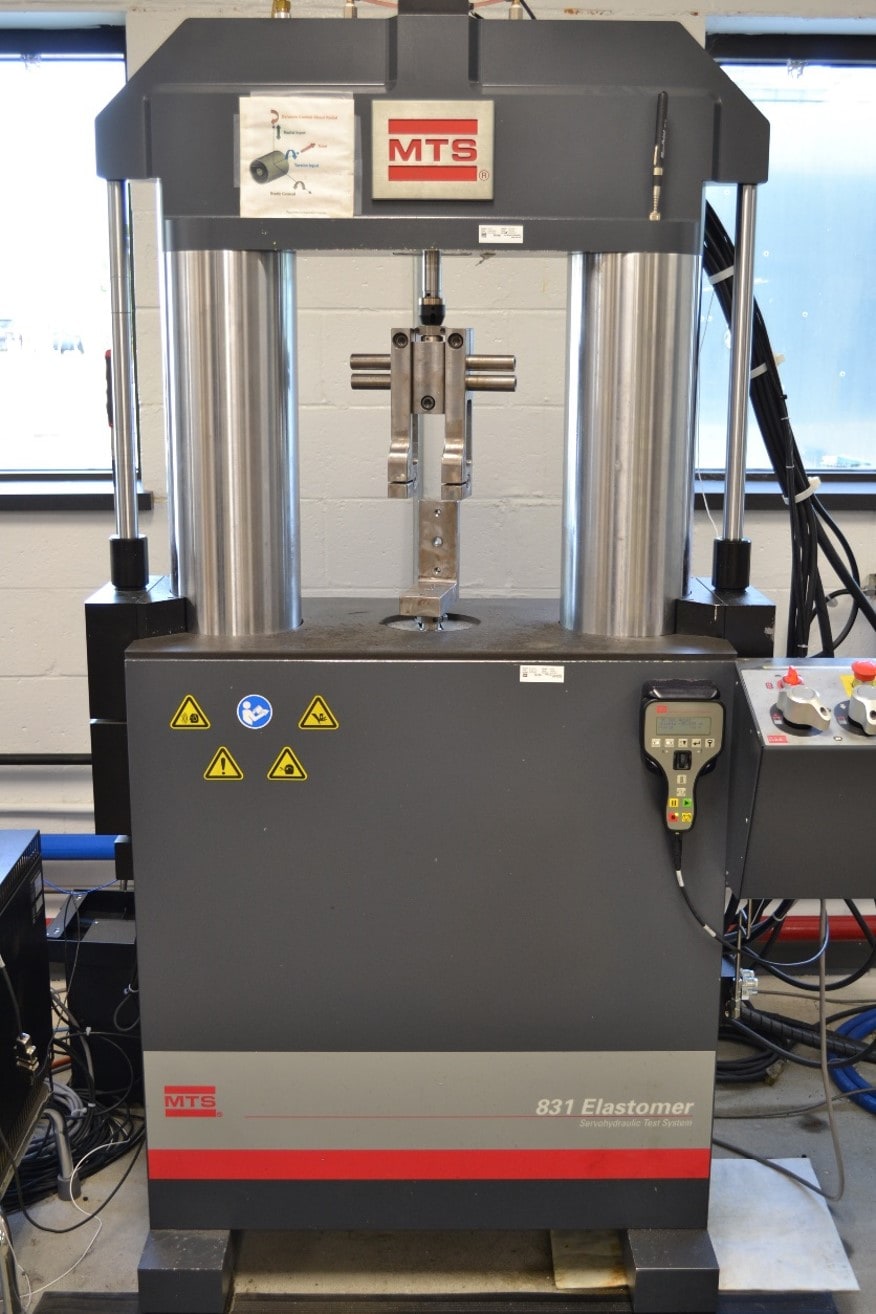

- MTS831 Elastomer Test System

- Designed for dynamic and static characterization of elastomeric components

- Test site controller runs MTS Elastomeric Software Suite

- Dedicated hydraulic supply to eliminate cross-talk

- Load capacity +/- 10kN

- Frequency sweeps up to 1000Hz

- Displacement of +/-20mm

- Crosshead heights of up to 400mm

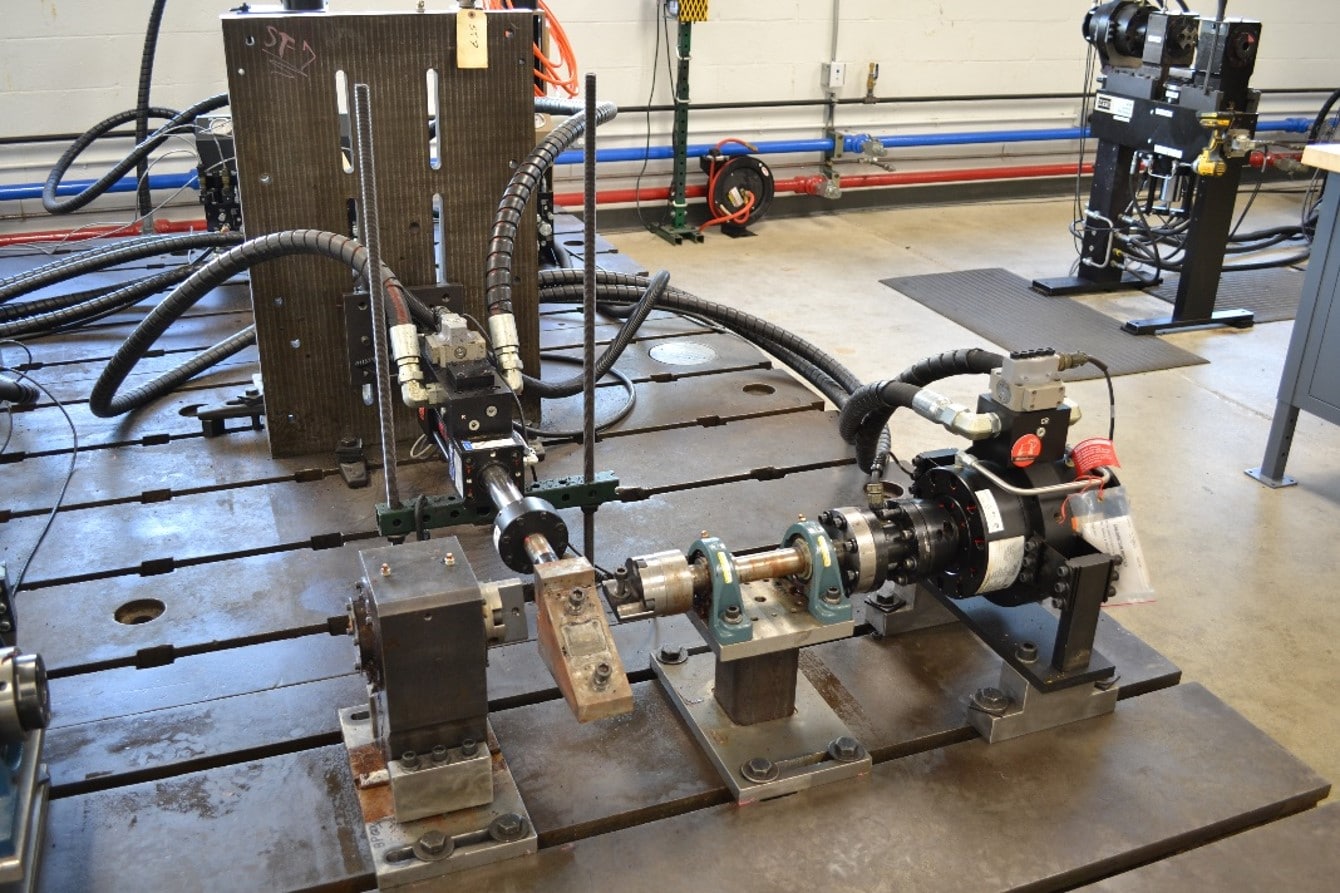

- MTS832 Bushing Test System (2x)

- Designed specifically for testing elastomeric bushings and other elastomeric components

- Test site controllers run MTS Elastomeric Software Suite

- Designed for durability testing and monitoring of static spring rates during test for rate degradation

- Bi-axial: linear and rotary

- Frequency sweeps up to 50Hz

- Load capacity +/-50kN

- Torque +/- 565N-M

- Rotational range +/- 50°

- Instron load frame for bushing push-in / push-out, load displacement curves, ultimate strength

- Load capacity +/- 250kN

The test lab is equipped with an array of linear actuators ranging from +/- 14.7kN 254mm disp. to +/- 100kN 152mm disp. Two free-standing rotary actuators. Both rated for +/- 565N-m +/- 50° rotation

- Flexible test setups using bed plates

- Vertical load frames, angle plates / stiff-backs

- Flexible test setups using bed plates

- Bedplate 2 axis (liner and rotational) used to validate bushings when MTS 832 machine capacity is filled.

- Additional capabilities available in ZLC China labs including a 3000 Hz machine used for EV powertrain mount characterization

3000HZ High Frequency Machine

- Equipment manufacturer

- M+P INTERNATIONAL Germany

- Capacity

- Max preload: 8KN

- Excitation force (sine): 8KN

- Frequency range: 50Hz -3000Hz

- Max amplitude of acceleration: 88 g

- Applications

- EV mount test

- High frequency study of rubber

- Study of hydro mount noise

- Customer specific /customized environmental “dirty water” test setup –

- Used to support validation of stabilizer bars for Tier 1 bar suppliers

- Testing two samples per setup with multi-channel control

- Mixture of Arizona Dust, Sodium Chloride and water

- Total test lab space of 5,000 ft²

- Two large bed plates totaling 340 ft² of multi axis rig setup area

- Room to expand into customer specific setups and requirements

- The Zhongli North America Tech Center accredited test lab is uniquely equipped for specialized elastomeric testing yet flexible for various other test configurations

- Experienced technicians who specialize in chassis component testing

- Fully accredited to ISO/IEC 17025:2017

- Competitive pricing

- Convenient location