What Is Rubber Molding?

Rubber’s combination of elasticity and durability makes it an ideal material for molded components. Manufacturers can utilize either natural elastomers and rubber materials or synthetic, chemically generated varieties. Rubber molding utilizes a shaped mold, heat, and pressure to form uncured rubber material into a finished part or product.

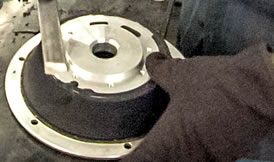

While different molding processes have different stages, rubber molding typically involves transferring pre-heated rubber into a metal mold cavity, heating the mold and using compressive force to cause chemical reactions like vulcanization and curing for cross-linking polymer chains, and then cooling the product at ambient temperatures to finally result in a part in the shape of the mold.