STERN RUBBER COMPANY IS COMMITED TO QUALITY

STERN’S PLAN FOR QUALITY

Link to our ISO Cert, click here

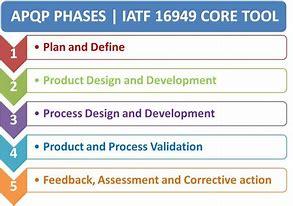

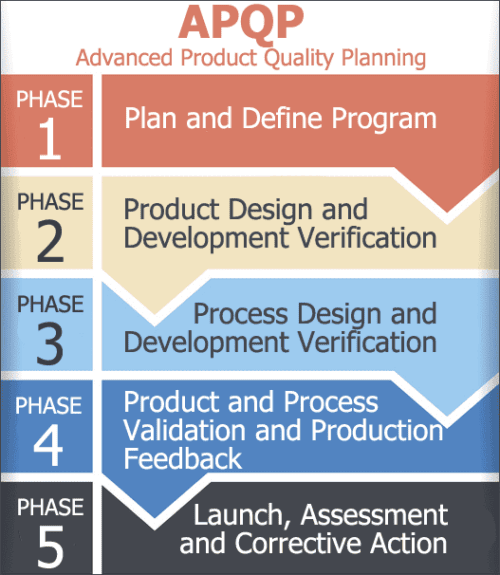

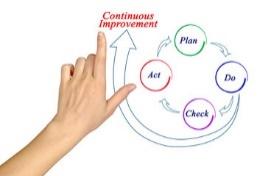

Stern Rubber Company utilizes APQP processes, we monitor and track internal Key Indicators, and we use the information to evaluate our current Quality System, identify areas for improvement, and to plan for future needs. In addition to inspection and documentation, the Stern Rubber Quality Department assists in the testing of compounds to ensure formula control and product compliance.

We also offer an offshore option for product. Our Purchasing and Quality Departments work closely with approved suppliers overseas, to provide custom rubber parts that will meet and exceed customer requirements. We perform an on-site audit at our suppliers’ offshore facilities, verify product, and communicate regularly with our offshore supply base.

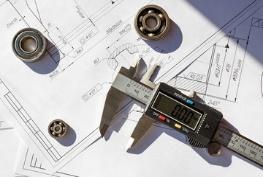

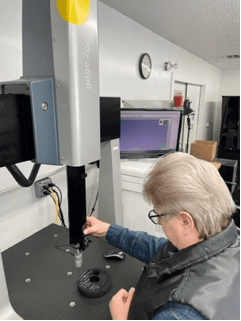

STERN RUBBER COMPANY’S QUALITY DEPARTMENT EQUIPMENT INCLUDES:

- MDR at our Plant 1 location and ODRs at our Plant 2 and Aitkin facilities

- Brown and Sharp Manual CMM with CMM Manager Software

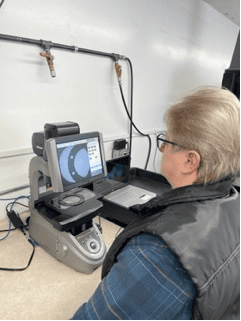

- Starrett Optical Comparator with Surface and Profile capabilities

- Keyence IM Series Vision System

- TensiTech Tensile Tester

- Makerbot Replicator2 3D printer

- Lab Oven and Lab Press

We have the measuring and test equipment needed to ensure that we are meeting our customers rigorous demands.